Modernize Your Equipment

Modernization

As equipment becomes older, less reliable and more difficult to replace, it becomes more costly to continue running and to maintain your system. In many cases, your aging equipment can't provide the connectivity, data and advanced analytics that you require to make improvements to your system and process.

At some point, you need to decide if an upgrade to newer technology and a new platform will produce an acceptable return on your investment. In addition to the obvious benefit of increasing your equipment's uptime and availability, an upgrade to the latest technology often will also provide you with more throughput on your equipment due to better cycle times, better connectivity to HMI, SCADA and MES packages, and newer technology such as reporting, advanced analytics, enhanced security, and remote access.

Let Phantom Technical Services help you determine the best path and evaluate your options for addressing your legacy equipment, to include Controllers, HMI's and Drive systems. We have the engineering expertise and experience to help you design and implement the best strategy for addressing the legacy equipment at your facility.

PLCs and Controllers

Phantom Technical Services has the knowledge and experience to help you upgrade the legacy PLCs and Controllers that are still running the critical processes and equipment in your facility. Our engineers have done dozens of modernization projects and have thousands of hours of experience working with Rockwell Automation, Siemens, Mitsubishi and Omron controllers, and modernizing to the newest platforms.

- Rockwell Automation PLC-5 - The majority of PLC-5 hardware, to include racks, power supplies, processors and I/O modules have been discontinued since June 2017 or earlier. In order to protect your investment in the PLC-5 family of processors, Rockwell Automation offers a migration kit that allows you to easily migrate to the newer platform of ControlLogix controllers, which offers you a competitive advantage by leveraging improvements in safety, security, mobility, connectivity and data collection. The ControlLogix platform will help you increase productivity and improve performance, uptime and your overall decision making process. Let Phantom Technical Services help you choose the best path to migrate your PLC-5 hardware and software based on your production needs, risk tolerance, budget and machine availability.

- Rockwell Automation SLC500 - While some of the SLC500 processors are still commercially available, many of the I/O modules, racks and power supplies are now officially End of Life or Discontinued. To stay ahead of ever changing market demands, many companies are working proactively to modernize their legacy SLC500 systems and are moving to the CompactLogix 5380 series of controllers. Phantom Technical Services can help you develop your upgrade strategy and develop a solution that will allow you to take advantage of the newer technology in CompactLogix, achieving better overall system performance by enhancing the performance, security, mobility and ease of data access in the CompactLogix system.

- Mitsubishi A to Q Series - The A series of Mitsubishi processors has not been available since 2008. In many cases, the remaining stock of A series of parts is very limited, which puts your production capabilities in jeopardy due to the high risk of failure of your equipment because of age. Let Phantom Technical Services help you modernize your legacy A series equipment to the new Q series processors. The Q series was introduced in 2002 and was designed to allow customers to transition from the A series without the need to rewire or replace any of your existing A series I/O modules.

HMIs

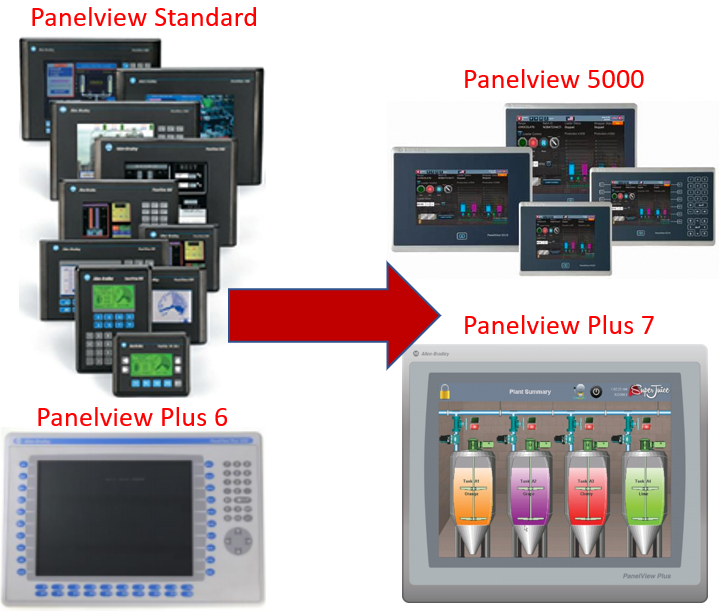

Rockwell Automation Panelview Products: Rockwell Automation has been building Human Machine Interface (HMI) Graphic Terminals for over 25 years. In that time, there have been new products and terminals introduced to meet customer's needs and adapt to changing technology. Several terminal families such as the original Panelview (or Panelview Standard) and the Panelview 'E' (or Panelview Enhanced) series have been discontinued for several years and are no longer available. Other terminal families, such as the PanelView Plus 6, are due to be discontinued on 9/30/2021.

Let Phantom Technical Services help you modernize your legacy Panelview terminals to one of the current series of terminals that are available today. We can help you select the proper family of available Panelview terminals based on the features that you need for your application. In many cases, the newer Panelview families can provide you features that were not available in previous generations, to include scalable vector based graphics, standard and wide screen displays up to 19", integration of FactoryTalk based alarms, built in navigation, and web enabled screen content.

Our engineers can also help you migrate your complex applications where replacing your PLC is not possible and the legacy network is no longer supported. Our team has worked with several partners that can help with a Gateway solution to allow your obsolete RS-232, DH-485, or DH+ networks to talk on an Ethernet I/P network.

Drives

Rockwell Automation Drives: Many companies depend on Variable Frequency Drives (VFDs) to control critical equipment within their facilities, to include pumps, electric fans, conveyors, HVAC systems and extruders. A number of the Rockwell Automation Drive types that customers have depended on for many years, such as the 1305, 1336, 1336 Plus II, and Bulletin 160 have been discontinued by Rockwell Automation and are no longer available as new product.

Many customers are choosing Phantom Technical Services to help them modernize to either the Powerflex 520 series or the Powerflex 750 series of drives. These two series were designed with the Connected Enterprise in mind and allow customers to benefit from products designed for easy access to data through a standard Ethernet I/P network that ultimately allows manufacturing to make better business decisions, provides more flexibility and reduced risk due to product obsolescence across the entire facility

Phantom Technical Services can help you address the manufacturing challenges that you are facing and help you embrace new technology to optimize your manufacturing processes and equip your employees for more productivity and efficiency.